Ụlọ ọrụ batrị na ihe ndị ọzọ kemịkalụ eji mmiri mmiri na-akwa akwa

Igwe ihe igwe pneumatic akwa nwere mmiri mmiri bụ akụrụngwa eji gwepịa ihe akọrọ ka ọ bụrụ ntụ ntụ, yana usoro ntọala dị ka ndị a:

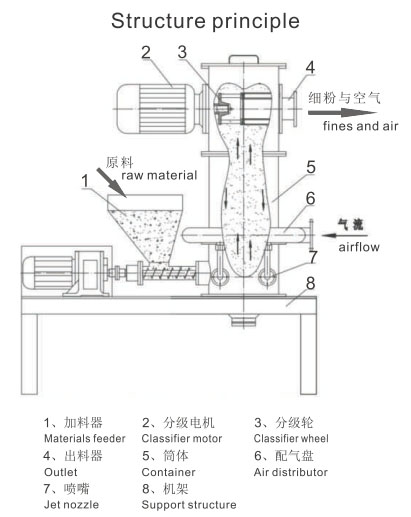

Ngwaahịa a bụ ihe na-ekpo ọkụ akwa na-ekpo ọkụ nke nwere ikuku mkpakọ dị ka ihe na-egwepịa ya. A na-ekewa ahụ igwe igwe n'ime akụkụ 3, ya bụ ebe a na-etipịa ihe, ebe nnyefe na mpaghara grading. Enyere mpaghara grading na wheel grading, na onye ntụgharị nwere ike gbanwee ọsọ ya. Ime ụlọ ahụ na-etipịa ihe mejupụtara nozul na-egwepịa, onye na-enye nri, wdg. Igwe mgbanaka sir na-enye diski dị n'èzí nnukwu ite na-egwepịa ihe jikọtara ya na nozulu na-etipịa ya.

Ihe na-abanye n'ime ụlọ na-etipịa ihe site na nri ihe. The mkpakọ ikuku nozzles n'ime-egweri ọnụ ụlọ na nnukwu ọsọ site na pụrụ iche a kwadebere anọ na-etipịa nozzles. Ihe na-enweta ngwa ngwa na ultrasonic jetting eruba na-emetụta ugboro ugboro ma na-adaba n'ebe etiti na-agbakọta ọnụ nke ọnụ ụlọ na-etipịa ruo mgbe ọ ga-egwepịa ya. Ihe a gbajiri agbaji na-abanye n'ime ụlọ akara ngosi na mgbago elu. N'ihi na wiil grading na-agba ọsọ na oke ọsọ, mgbe ihe na-arịgo, ihe ndị ahụ dị n'okpuru ike centrifugal nke sitere na grading rotors yana ike centripetal nke sitere na viscosity nke ikuku. Mgbe ihe ndị ahụ dị n'okpuru ike centrifugal dị ukwuu karịa ike centripetal, ihe ndị ahụ na-adịghị ahụkebe nke nwere nnukwu dayameta karịa ihe ndị a chọrọ agaghị abanye n'ime ime ụlọ nke wiil grading ma laghachi n'ime ụlọ na-etipịa ka a gwepịa ya. Ihe dị mma nke na-agbaso dayameta nke ihe ndị a chọrọ ga-abanye na wiil nke grading wee banye na nkesa cyclone nke ime ụlọ nke wheel grading na ikuku na-anakọta ma na-anakọta ya. A na-ahapụ ikuku a kpochara site na onye na-ebu ikuku mgbe ọgwụgwọ akpa nzacha gasịrị.

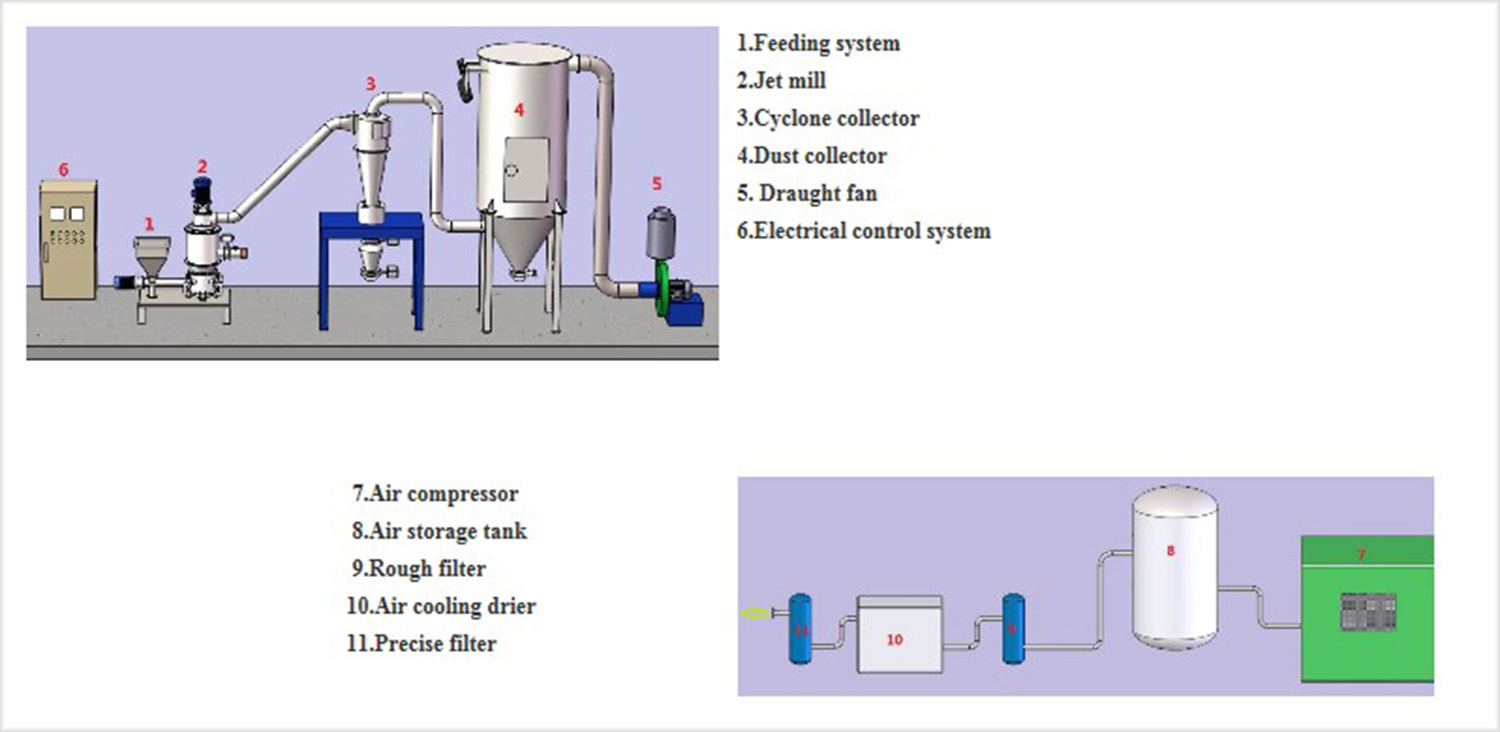

The pneumatic pulverizer mejupụtara ikuku compressor, mmanụ remorer , gas tank, ifriizi draya, air filter, fluidized bed pneumatic pulverizer, cyclone separator, onye nchịkọta, ikuku intaker na ndị ọzọ.

Ihe ngosi zuru oke

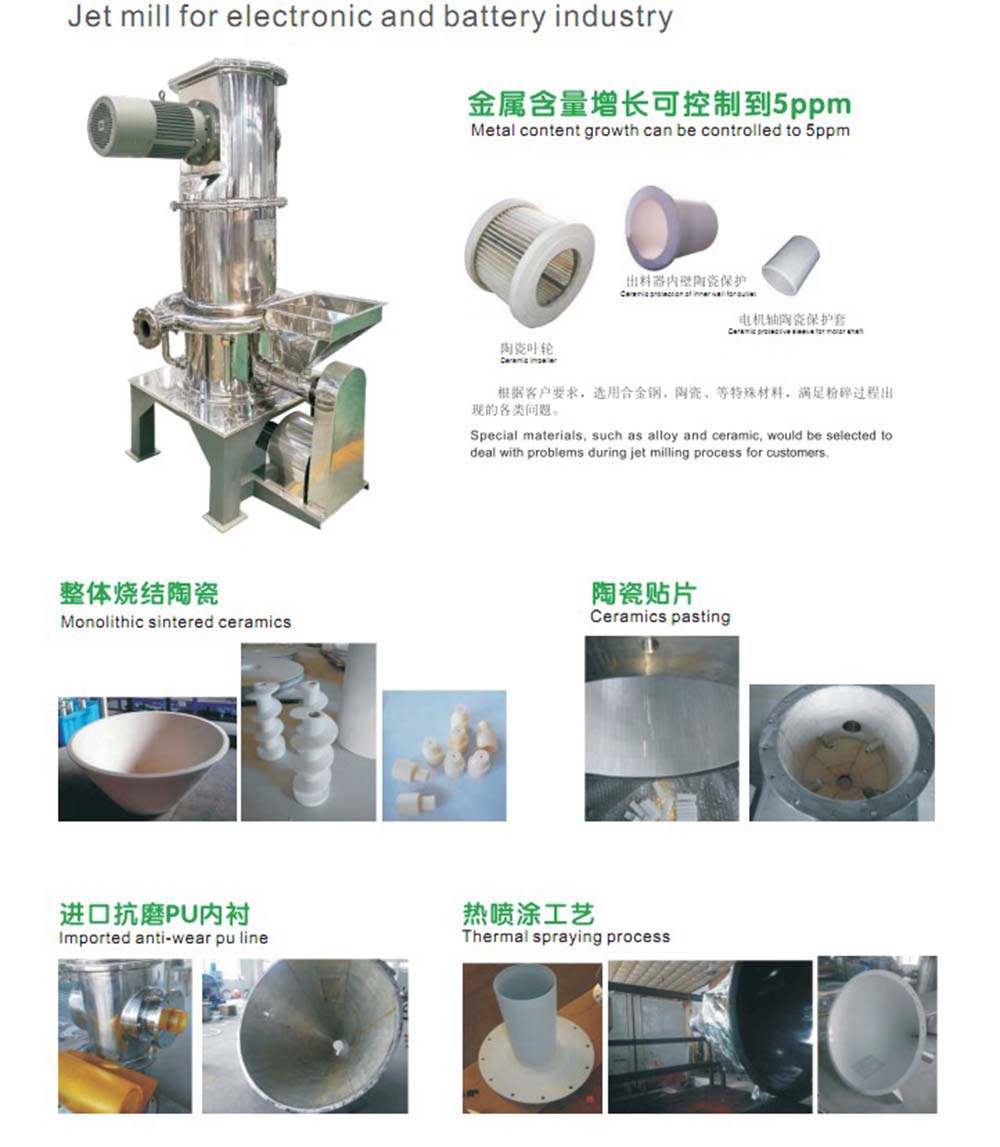

Tapawa seramiiki na PU lining na akụkụ igwe nri niile na-akpọtụrụ ngwaahịa iji zere igwe mkpofu na-ebute nsonaazụ na-adịghị mma nke ngwaahịa ọnụ.

1.Precision seramiiki mkpuchi, 100% kpochapụ mmetọ ígwè site na nhazi nhazi ihe iji mee ka obi sie ike na ịdị ọcha nke ngwaahịa. Kwesịrị ekwesị maka ihe ndị a chọrọ n'ígwé, dị ka cobalt high acid, lithium manganese acid, lithium iron phosphate, Ternary Material, lithium carbonate na acid lithium nickel na cobalt wdg batrị cathode ihe onwunwe.

2. Enweghị ịrị elu na okpomọkụ: Ọnọdụ okpomọkụ agaghị abawanye ka a na-akụtu ihe ndị ahụ n'okpuru ọnọdụ ọrụ nke mgbasawanye pneumatic na ọnọdụ okpomọkụ dị na oghere igwe nri na-edobe nkịtị.

3.Endurance: A na-etinye ya na ihe ndị nwere Mohs Hardness n'okpuru ọkwa 9. ebe ọ bụ na mmetụta egwe ọka na-agụnye nanị mmetụta na nkukota n'etiti ọka karịa nkukota na mgbidi.

4.Energy-dị irè: Ịchekwa 30% -40% tụnyere ndị ọzọ ikuku pneumatic pulverizers.

Enwere ike iji gas 5.Inert mee ihe dị ka mgbasa ozi maka igwe ọkụ na-ere ọkụ na ihe mgbawa.

6. A na-egweri usoro dum, ájá dị ala, ụda dị ala, usoro mmepụta dị ọcha na nchebe gburugburu ebe obibi.

7. Usoro ahụ na-anabata njikwa ihuenyo mmetụ nwere ọgụgụ isi, ọrụ dị mfe na njikwa ziri ezi.

8.Usoro kọmpat: ụlọ nke isi igwe mejupụtara sekit na-emechi maka ikpochapụ.

The eruba chaatị bụ ọkọlọtọ-egwe ọka nhazi, na ike gbanwee maka ndị ahịa.

| ihe nlereanya | QDF-120 | QDF-200 | QDF-300 | QDF-400 | QDF-600 | QDF-800 |

| Nrụgide arụ ọrụ (Mpa) | 0,75-0,85 | 0,75-0,85 | 0,75-0,85 | 0,75-0,85 | 0,75-0,85 | 0,75-0,85 |

| Oriri ikuku (m3/min) | 2 | 3 | 6 | 10 | 20 | 40 |

| Dayameta nke ihe oriri (ntupu) | 100-325 | 100-325 | 100-325 | 100-325 | 100-325 | 100-325 |

| Ịdị mma nke nchipịa (d97μm) | 0,5-80 | 0,5-80 | 0,5-80 | 0,5-80 | 0,5-80 | 0,5-80 |

| Ike (kg/h) | 0,5-15 | 10-120 | 50-260 | 80-450 | 200-600 | 400-1500 |

| Ike arụnyere (kw) | 20 | 40 | 57 | 88 | 176 | 349 |

| Ihe onwunwe | Ụdị | Dayameta nke nri ahụ | Dayameta nke irighiri ihe ewepụrụ | Mpụta(n'arọ/h) | Oriri ikuku (m3/min) |

| Cerium oxide | QDF300 | 400 (Ntupu) | d97,4.69m | 30 | 6 |

| Ọkụ na-egbochi ọkụ | QDF300 | 400 (Ntupu) | d97,8.04m | 10 | 6 |

| Chromium | QDF300 | 150 (ntupu) | d97,4.50μm | 25 | 6 |

| Phrophyllite | QDF300 | 150 (ntupu) | d97,7.30μm | 80 | 6 |

| Ọkpụkpụ | QDF300 | 300 (ntupu) | d97,4.78m | 25 | 6 |

| Talcum | QDF400 | 325 (ntupu) | d97,10μm | 180 | 10 |

| Talcum | QDF600 | 325 (ntupu) | d97,10μm | 500 | 20 |

| Talcum | QDF800 | 325 (ntupu) | d97,10μm | 1200 | 40 |

| Talcum | QDF800 | 325 (ntupu) | d97,4.8m | 260 | 40 |

| Calcium | QDF400 | 325 (ntupu) | d50,2.50μm | 116 | 10 |

| Calcium | QDF600 | 325 (ntupu) | d50,2.50μm | 260 | 20 |

| Magnesium | QDF400 | 325 (ntupu) | d50,2.04μm | 160 | 10 |

| Alumina | QDF400 | 150 (ntupu) | d97,2.07μm | 30 | 10 |

| Ike pel | QDF400 | 300 (ntupu) | d97,6.10μm | 145 | 10 |

| Quartz | QDF400 | 200 (ntupu) | d503.19 μm | 60 | 10 |

| Barite | QDF400 | 325 (ntupu) | d501.45 μm | 180 | 10 |

| Onye na-eme ụfụfụ | QDF400 | d5011.52μm | d501.70μm | 61 | 10 |

| Ala kaolin | QDF600 | 400 (Ntupu) | d50,2.02μm | 135 | 20 |

| Lithium | QDF400 | 200 (ntupu) | d501.30μm | 60 | 10 |

| Kirara | QDF600 | 400 (Ntupu) | d503.34 μm | 180 | 20 |

| PBDE | QDF400 | 325 (ntupu) | d97,3.50μm | 150 | 10 |

| AGR | QDF400 | 500 (ntupu) | d973.65μm | 250 | 10 |

| Graphite | QDF600 | d503.87 μm | d501.19 μm | 700 | 20 |

| Graphite | QDF600 | d503.87 μm | d50, 1.00μm | 390 | 20 |

| Graphite | QDF600 | d503.87 μm | d500.79 μm | 290 | 20 |

| Graphite | QDF600 | d503.87 μm | d500.66 μm | 90 | 20 |

| Concave-convex | QDF800 | 300 (ntupu) | d97,10μm | 1000 | 40 |

| silicon ojii | QDF800 | 60 (ntupu) | 400 (Ntupu) | 1000 | 40 |