Ngwa maka Jet Mil

1.nke na-ebu n'èzí, gbochie ihe ahụ ịbanye n'ime, mgbe ahụ jam.

2.valve na valvụ isi bụ akụkụ nkedo, enweghị nrụrụ mgbe ejiri ogologo oge mee ihe.

Usoro 3.CNC na-eme ka ọ dị mma.

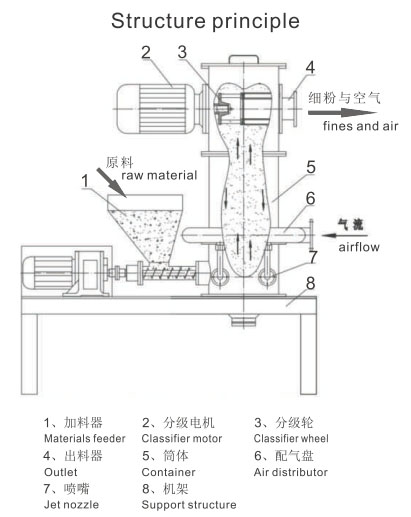

Nkọwa

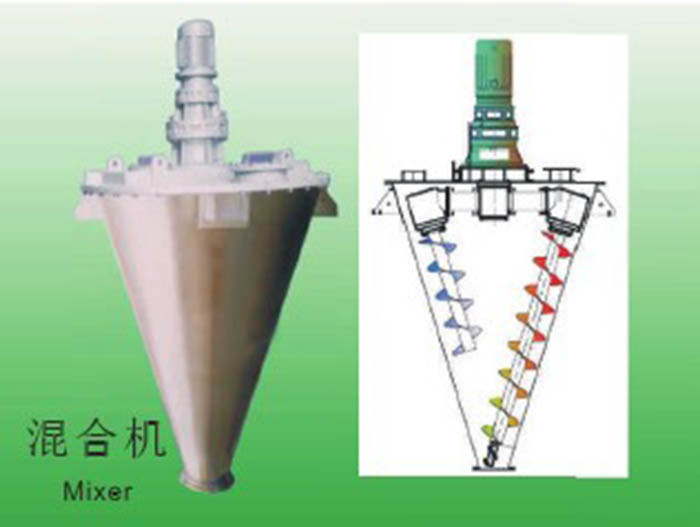

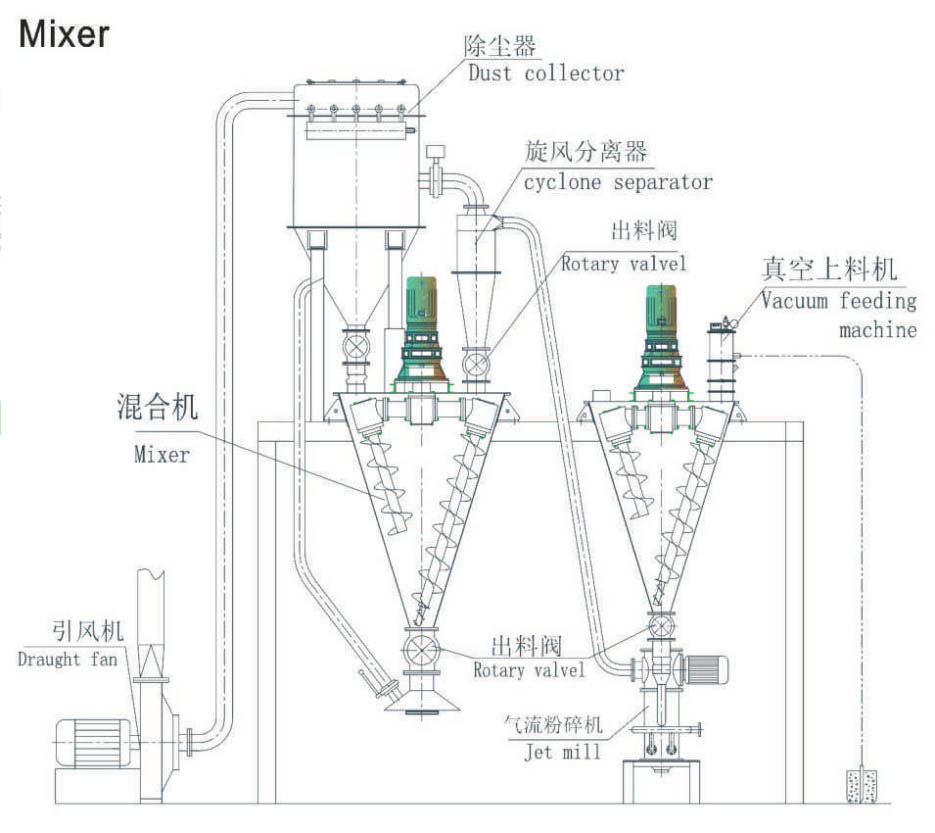

DSH okpukpu abụọ ịghasa igwekota integrates ntụ ntụ, granule na mmiri mmiri agwakọta. A na-emecha ntụgharị nke igwe ejima ịghasa igwekota site na otu moto na ndị na-ebelata cycloid. Site na ịgwakọta asymmetric site na skru abụọ, a ga-agbasawanye ihe na-akpali akpali ma na-akpalite ọsọ ga-eme ngwa ngwa. A na-akwalite igwe ngwakọta ahụ site na spirals abụọ asymmetric nke ntụgharị ngwa ngwa, na-eme ogidi abụọ na-abụghị nke na-agbago elu site na mgbidi cylinder. Na-atụgharị ogwe aka chụpụrụ gburugburu gburugburu orbit, na-eme ka spiral ihe dị iche iche larịị n'ime stud na envelopu, dislocation akụkụ nke ihe a na-akwalite, akụkụ nke ọzọ nke ihe a na-atụba ịghasa, nke mere na iji nweta zuru okirikiri ibu ihe mgbe niile emelitere. Ihe abụọ ahụ a kpọtụrụ aha n'elu na-ejikọta ya na oghere concave nke etiti ahụ, na-eme ka ihe na-asọda ala ma na-agbakwunye oghere dị n'okpuru ebe ahụ, si otú a na-emepụta mgbasa ozi convective.

Njirimara

1.Homogeneous ngwakọta

2.Short ngwakọta oge 5-15 nkeji

3.Mwepu dị ọcha & enweghị ihe ọ bụla

4.Central mgbapu valvụ:

Eletrọnịkị, pneumatic, akwụkwọ ntuziaka (nhọrọ)

valvụ bọọlụ, valvụ flaapu, valvụ ọnụ ụzọ mma, valvụ nru ububa (nhọrọ)

5.Main shaft akara: ihe mkpuchi na ikuku na-ekpochapụ

6.Drive: Siemens moto, cycloid ma ọ bụ gia reducer

7.Limit/safety mgba ọkụ (nhọrọ)

8. Heating / jụrụ jaket nhọrọ)

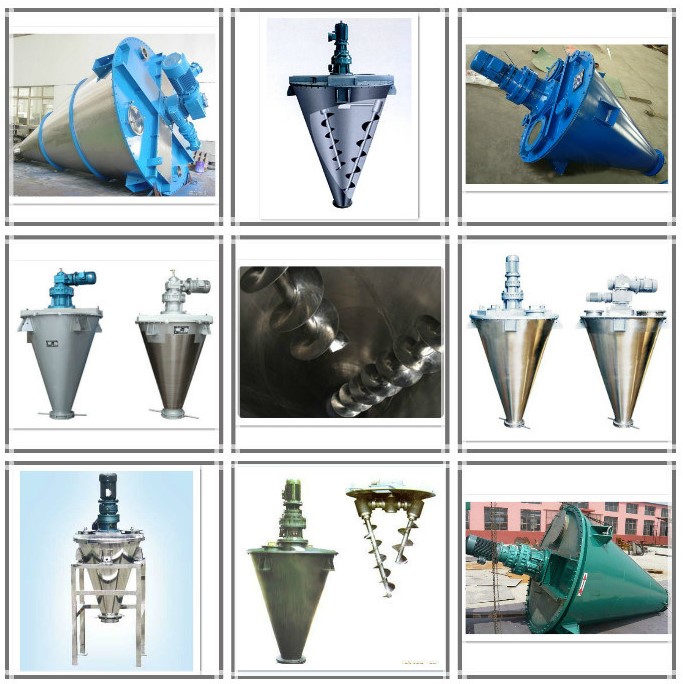

Ngwa igwekota cone:

1.Applicable ihe onwunwe nkezi nke ndị ogbenye, na ntụ ntụ ahụ bụ ihe dịtụ nnukwu ihe;

2.Suitable maka seramiiki glaze na-agwakọta usoro dị nro, ihe ndị na-emepụta ihe anaghị eri nri ma ọ bụ agbaji;

3.The okpomọkụ-sensitive ihe agaghị ekpo oke ọkụ;

4.In na ntụ ntụ - ntụ ntụ ntụ ntụ usoro dị mfe ịgbakwunye na-arụ ọrụ ọnọdụ ma ọ bụ na-enye a mmiri mmiri na a plurality nke ịgba mmepụta pụtara;

5.The ala valvụ nke dislocation adaba ihe onwunwe, ebe ọ bụ na ala nke spiral ọ dịghị fixtures, n'ihi ya, ọ dịghị nrụgide nri phenomenon.

Ụkpụrụ ọrụ:

Ihe igwekota rịbọn okpukpu abụọ nwere tankị kwụ ọtọ, mkpuchi elu nwere oghere (ma ọ bụ na-enweghị) oghere, otu ogwe nke nwere akwa akwa akwa abụọ, ngalaba nnyefe, etiti nkwado, mmewere akara, ihe nrụpụta na ihe ndị ọzọ. Mpempe rịbọn na-abụkarị okpukpu abụọ. Mpụta oyi akwa rịbọn na-eme ka ihe na-ejikọta site na nsọtụ abụọ ruo etiti na n'ime oyi akwa rịbọn na-eme ka ihe gbasaa site na etiti ruo na nsọtụ abụọ. Akụrụngwa na-etolite vortex n'oge mmegharị ugboro ugboro, a na-enwetakwa ngwakọta nke otu.

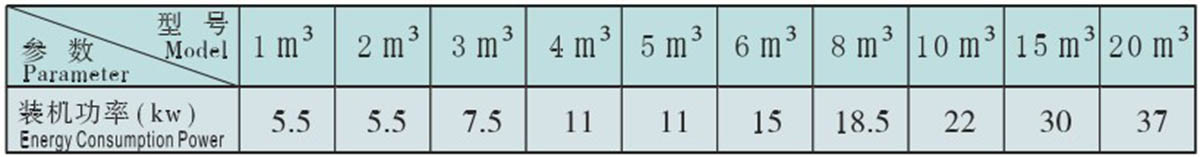

Arụmọrụ & atụmatụ:

1. Ihe: igwe anaghị agba nchara 304 / 316L ma ọ bụ obere ígwè Q235;

2. Ngwọta dị n'elu: agba (nchara dị nro), polish / sandblasting (igwe anaghị agba nchara);

3. Ribbon agitator: okpukpu abụọ & ntụziaka abụọ;

4. Ngwakọta mixer: kehoraizin, tank nke U;

5. Ogwe: kehoraizin, oghere, ihe jikọrọ otu ogwe;

6. Oge ngwakọta: 5-15 nkeji;

7. Ụdị ọrụ: ngwakọta ogbe;

8. Mbelata ọsọ ọsọ: cycloid reducer;

9. Ọsọ ntụgharị: ọsọ ọsọ;

10. Main shaft akara: (Teflon) nri nri ma ọ bụ ikuku ihicha akara;

11. Mmeghe: ntinye nri, oghere oghere, na ọdụ ụgbọ mmiri nyocha / njikọ;

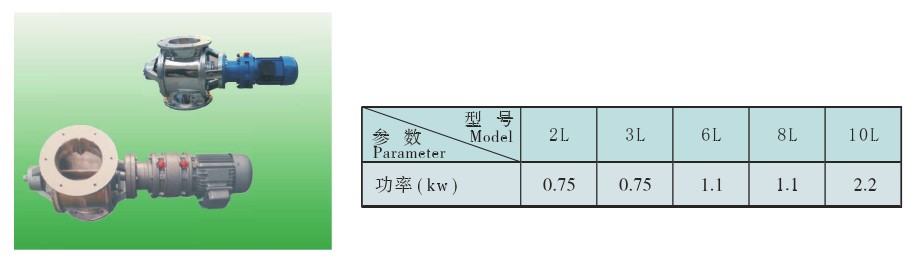

12. valvụ mgbapụta: pneumatic ma ọ bụ ntuziaka flap na-ahapụ valve;

13. Ọnọdụ ọrụ: NPT (nrụgide nkịtị na okpomọkụ);

14. Ọ bụghị arọ ọrụ: igwekota enweghị ike malite na loading ihe;

15. Ike ọkụ: 220V 50HZ otu oge / 380V 50HZ 3 nkeji;

16. Igwe eletrọnịkị na-abụghị nke mbụ (moto, ihe eletrọnịkị, kabinet njikwa);

Ọdụ ụgbọ elu

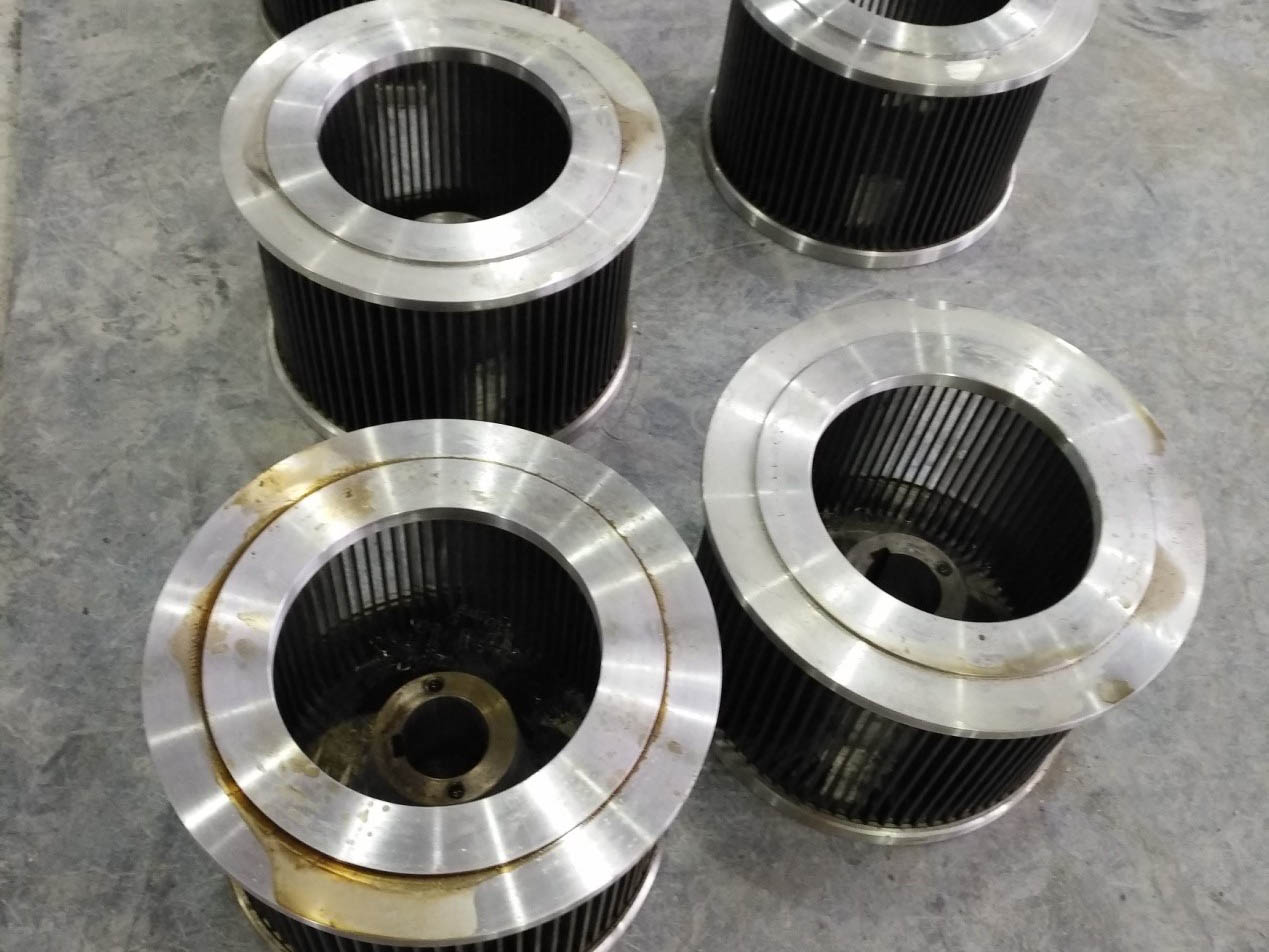

Wheel ekewapụtara